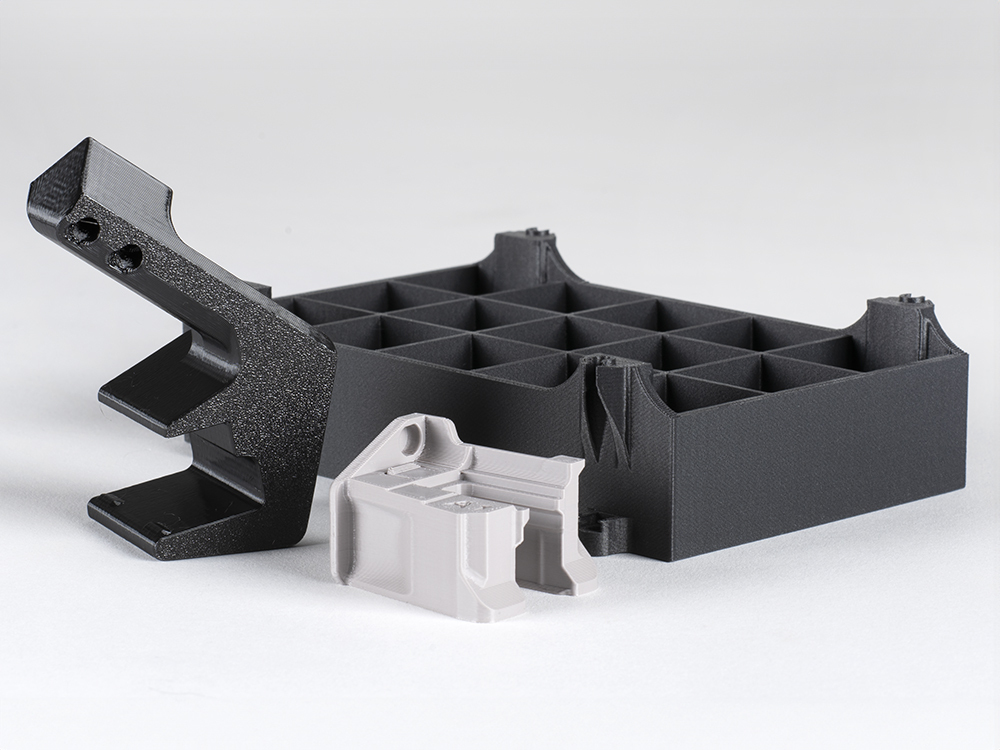

Prototyping

Produce your prototypes using popular materials, such as PLA, PETG, ABS, ASA and more!

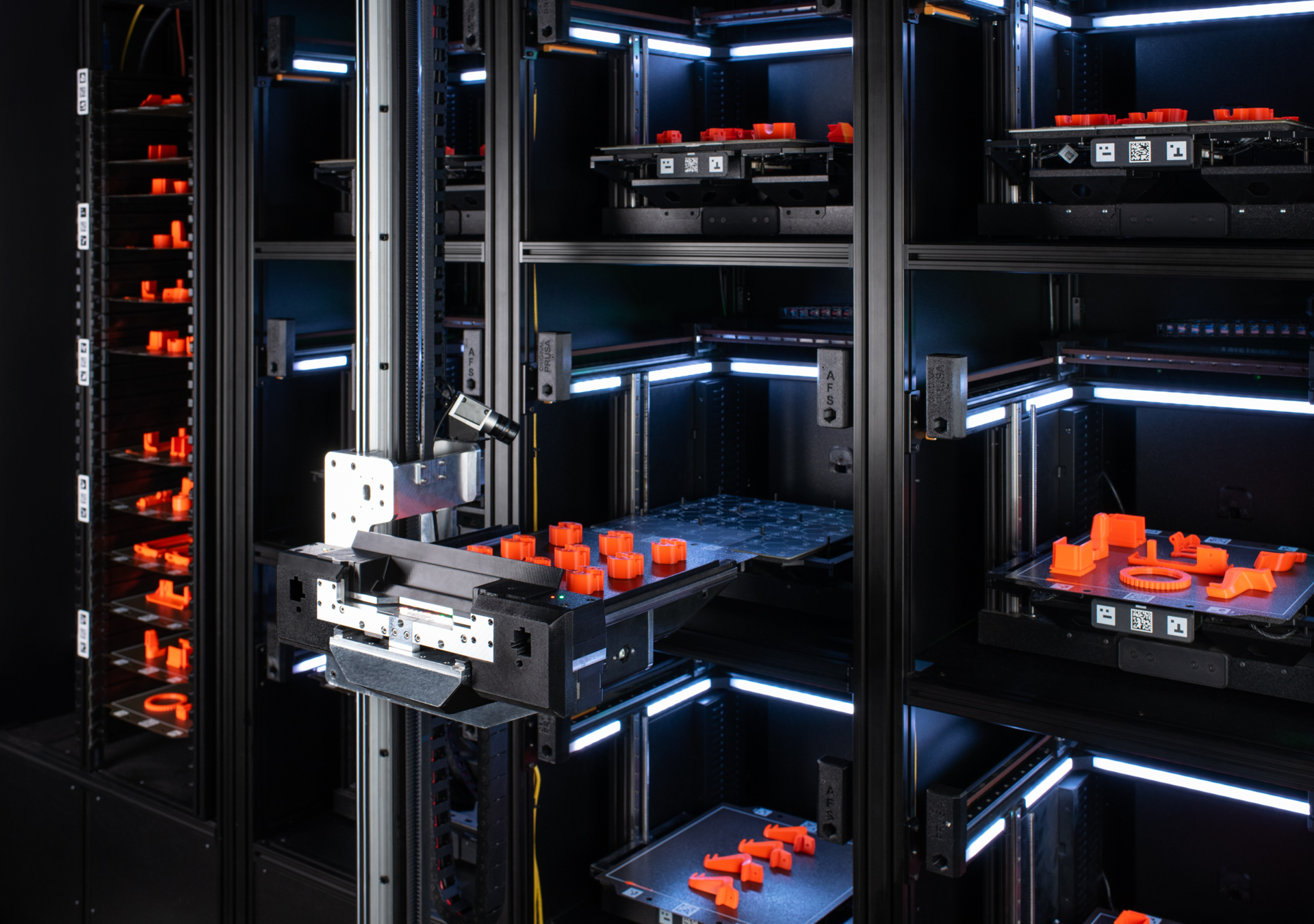

Automated Farm System by Prusa Research is a 3D printing production facility, a perfect solution for rapid prototyping, small-series production and a wide range of industrial uses.

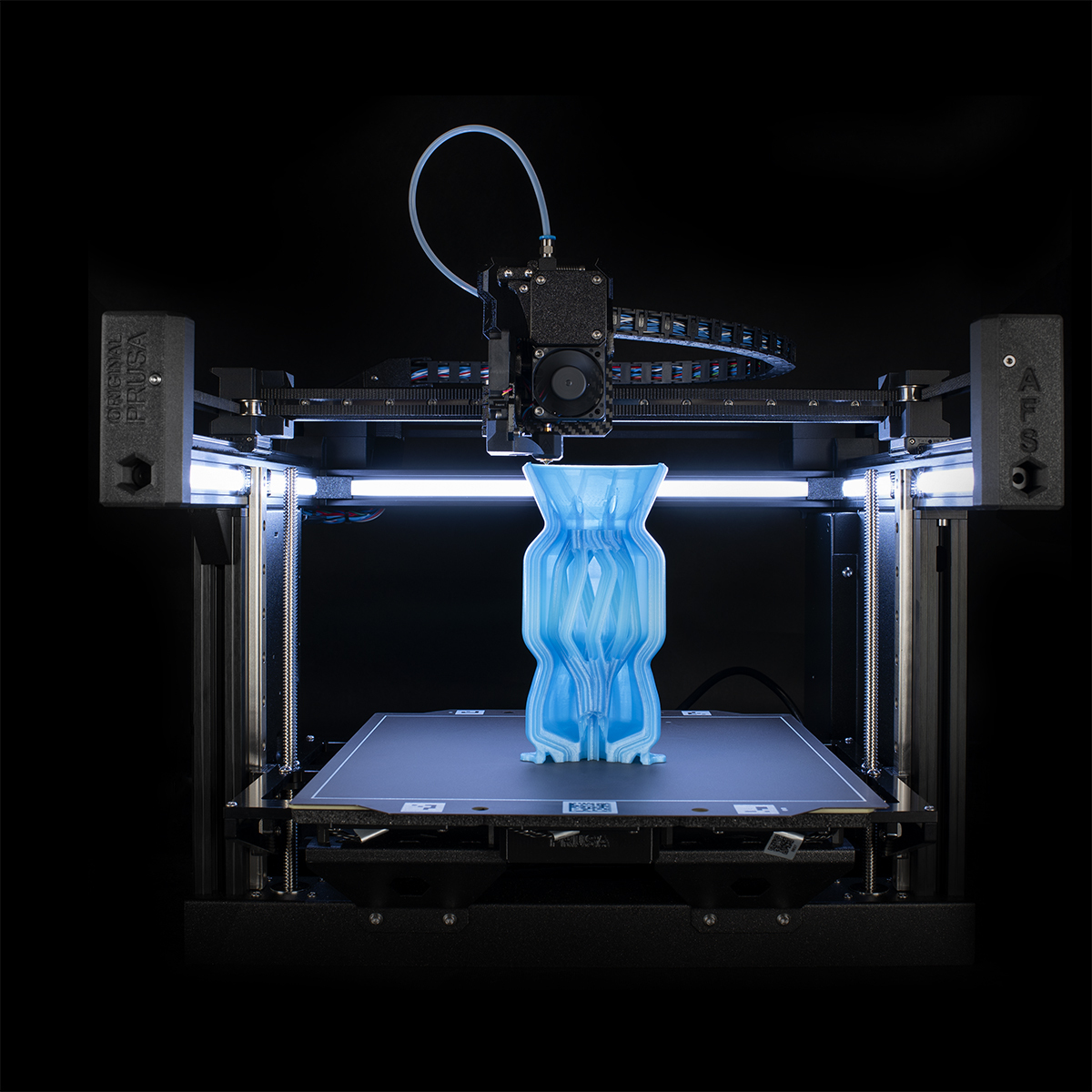

The AFS is equipped with 9 fast CoreXY Input Shaper 3D printers, each with a print volume of 260×260×170 mm. The automated arm delivers finished prints into the integrated smart storage so the printer can resume operation as quickly as possible. If needed, it is possible to expand the AFS in increments of 9, allowing for increased printing capacity to meet growing demand.

PRUSA PRO AFS is a 3D printing production facility for both large and small businesses. With a wide range of supported thermoplastics and autonomous operation, the AFS is ideal for small-batch production, rapid prototyping, manufacturing of highly customized items, R&D and other areas. The internally developed software manages all parts of the production process.

Produce your prototypes using popular materials, such as PLA, PETG, ABS, ASA and more!

Produce spare parts only when necessary, reducing lead times and inventory costs.

The AFS is capable of printing products for direct use or distribution.

The Prusa Pro AFS was revealed as a high-tech prototype, our vision for the future of manufacturing, at the Dubai Expo 2020. Now, the vision becomes a reality. In Prusa Research, we run a manually managed 3D print farm with more than 600 3D printers in a constant 24/7 operation, so a fully automated solution was the next logical step. |

| Number of 3D printers | 9 with the possibility of incremental expansion by a multiple of 9 |

| Print volume | 260×260×170 mm / 10.63×10.63×6.69 in. |

| Print surface | Removable spring steel sheets, multiple surfaces available (Smooth, Textured, Satin, PA Nylon) |

| Nozzle | Easy to swap nozzles, V6-compatible, up to 290 °C, nozzle cleaning system |

| Extruder | Next-generation extruder (Nextruder), LoadCell-based automatic mesh bed leveling, built-in filament sensor and accelerometer |

| Heatbed | Segmented heatbed, up to 115 °C |

| Print extraction and delivery | The AFS is capable of delivering finished prints to a storage system and placing an empty print sheet onto the printer. |

| Farm management software | Prusa Connect, automatic task scheduling, print queuing, maintenance scheduling |

| 3D printer kinematics | CoreXY with Input Shaper |

| Other features | Easy to swap printers, remote access, optical print quality monitoring, emergency stop switch, safe access to finished prints, custom-made HEPA filtration (designed for 3D printing) |

Interested in the Prusa Pro AFS? Leave your contact info and we'll get back to you!